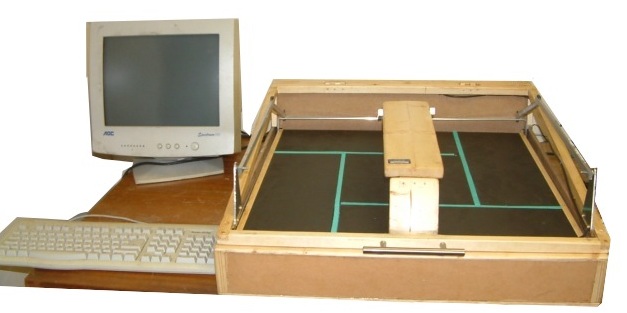

Baby products Tog Tester

An instrument to measure the thermal resistance of baby products

in the range from 2 to 5 tog. in accordance with BS 8510 using the

guarded hotplate principle

(Principles of tog testing).

The equipment consists of a long life anodized aluminium hotplate assembly,

a computer control unit and a set of air temperature sensors.

The test procedure is is fully automatic, no additional calculation required.

The instrument is designed with ease of long term maintenance in mind.

The control system is based on a standard PC using only open-source software,

so maintenance does not depend on the continued existence of suppliers

Simple push-button test operation.

Place a conditioned product on the hotplate.

Some products, eg jump suits, may need to be cut to lay flat on the bed.

Press the start button. When test is complete, a green light comes on.

The tog value can be read from a local VDU and a certificate printed from a network PC.

The control system is based on a Linux PC, intended primarily to act as

a network data server, although local output is available.

The operating system, data acquisition system and test procedure are

entirely open-source software, so can be maintained by third parties.

Supervisory software includes status indicators for all heaters, and

real-time graphical display of tog value and temperatures of air,

hotplate and guards.

Client software for printing certificates on a PC running Microsoft

Windows™ is included.

Air conditioning

To meet British Standards the air conditioning must provide air

temperature stable to ±0.1°C. This can be achieved if a standard air

conditioner is run in "proportional" mode and a large plenum is

provided to smooth the airflow, for example distributing the air

through the room ceiling cavity, or if the air conditioner includes a

regulated post-cooling heater to provide precise temperature control.

Air conditioning requirements

Price

BS8510 instrument complete with delivery and installation in the mainland UK is £4500

Does not include air conditioning, reference materials etc.

Price exclude VAT, which for EU customers is charged at the UK rate.

For overseas orders, please call.

Technical details

This is a precision instrument requiring minimal calibration and capable

of 1% accuracy given suitable environmental controls.

Hotplate and guard plate temperature 33°C ±0.1°C

Temperature variations across surface and between plates less than 0.02°C

Over-temperature protection on all heaters

Heat output during test 3-15W. Extraneous heatflow less than 20mW.

Guard temperature control by thermopile sensor with chopper stabilised

thermally controlled amplifiers giving uncalibrated accuracy better than 0.005°

Absolute temperature sensing by platinum resistance sensor with chopper

stabilised amplifier giving stability of around 0.1° per year.

The instrument measures the heatflow and average plate and air temperatures

over the hotplate area using five-point probes.

Dimensions

- Main hotplate: 25cm x 25cm

- Working area, with guard plates: 47cm x 47cm

- Instrument size 50cm x 70cm

Warm-up time approx 5 hours.

Test time: depends on air temperature stability and product construction. Typically about one hour.

Hotplate powered from a stabilised DC supply with voltage and current measured independently and continuously.

Computer interface includes auto-calibration facility which guarantees voltage measurements to 0.1%

Software implements procedure BS8510:2009,7.2.2. Other procedures available on request.

All system temperatures over entire measurement cycle recorded for validation.

Local VDU output can report results and test progress.

Compliant with CE regulations for electrical safety and EMC.